-

ProductsAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

-

ApplicationsAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

-

ProcessAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

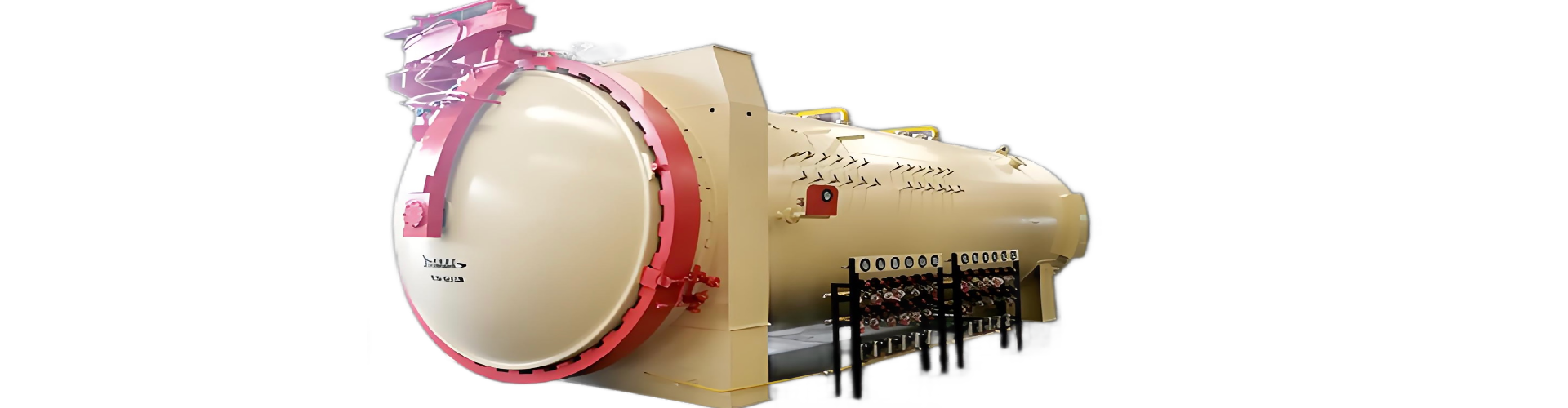

Autoclave

The FRP hot press tank process is a high-temperature and high-pressure forming method mainly used in the manufacturing of carbon fiber composite materials. The following is a detailed introduction to the FRP hot press tank process:

1、 Process principle

Lay the carbon fiber prepreg on the mold according to the layer requirements, then seal the blank in a vacuum bag and place it in a hot press tank. In a vacuum state, the material is softened and tightly adhered to the mold by using the uniform temperature and pressure provided by the hot press tank equipment through temperature rise, pressure rise, insulation, temperature drop, and pressure relief procedures, ultimately achieving solidification and molding.

2、 Process characteristics

High precision in temperature and pressure control: Hot press equipment can provide precise temperature and pressure control to ensure the quality of product molding.

Wide applicability: This process is suitable for manufacturing carbon fiber composite parts with complex shapes and large areas, and is widely used in fields such as aerospace, transportation, and sports equipment.

Mature technology: The hot press can process has been developed and applied for a long time, and the technology is mature, stable, and reliable.

3、 Process flow

Preparation process: including the preparation of molds, carbon fiber prepreg, and auxiliary materials.

Material laying: Cut, lay and compact the carbon fiber prepreg according to the design requirements.

Curing preparation: Carry out preparation work such as bagging, cutting and laying of auxiliary materials.

Solidification molding: Heating and pressurization are carried out in a high temperature and high pressure environment to solidify the material into shape.

Testing and post-processing: Conduct visual inspection, ultrasonic or X-ray non-destructive testing on the product, and make necessary adjustments to meet the design requirements.

Contact Us

Telephone:

E-mail:

Address:

Room 821, Building 4, China Merchants Wanbo Mansion, Hanxi Avenue East, Nancun Town, Panyu District, Guangzhou City

©2024 Guangzhou KUKE Chemicals Co.,LTD. Business License

SEO Tags Power by:www.300.cn

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.