-

ProductsAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

-

ApplicationsAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

-

ProcessAlways committed to the promotion of advanced technology in China's composite materials industry, to provide quality products and services

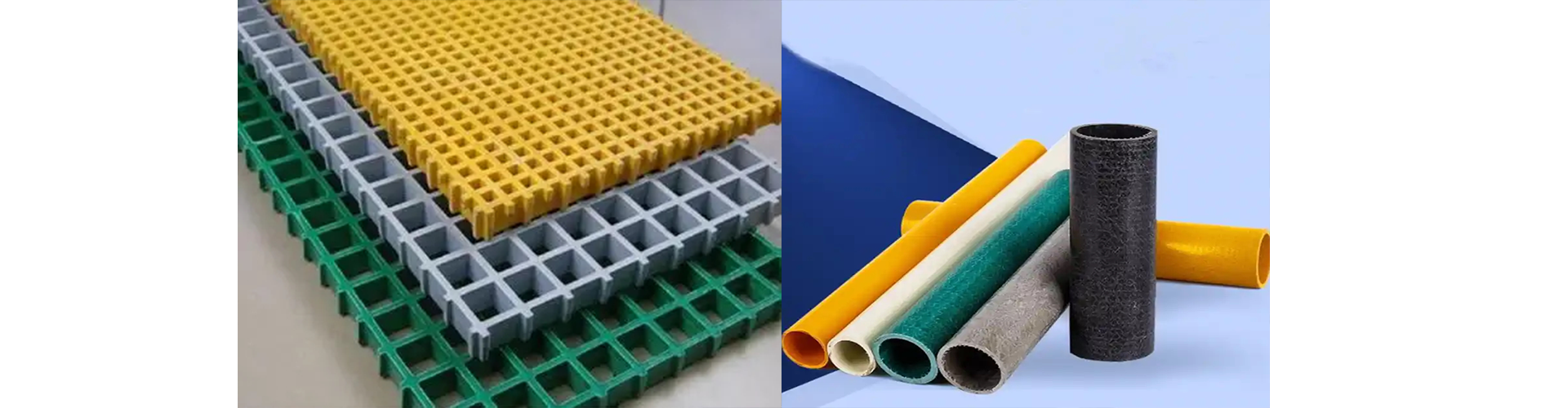

Pultrusion

An automated, high-volume, continuous process in which glass rovings are "pulled" through a heated die to form a contoured shape.

Pultrusion is a continuous and highly automated process that is cost-effective in the mass production of constant cross-section parts. Pultruded standard profiles include I-beams, channels, angles, beams, bars, bars, pipes and plates, which penetrate almost every market. The pultrusion process relies on a track-type traction system that pulls the fibers through a bath of catalytic resin and into a heated metal die. As the wetted fiber passes through the die (forming the shape of the desired profile), it is compacted and solidified. The cured profile is then cut to length with an automatic saw synchronized with the line speed.

An alternative wet-laid system injects resin directly into a heated mold and multiple fiber streams can be pultruded in a single mold with multiple cavities. To form a hollow or porous part, the wetted fibers are wrapped on a heated mandrel extending through a die. If off-axis structural strength is desired, the mat and/or stitched fabric may be folded into a material package prior to entering the mold. The pultrusion applications typically use glass fibers and thermosetting resins such as polyesters, vinyl esters, epoxies, and phenolics. Depending on the performance requirements of the final product, carbon fiber and other knitted and mixed reinforcement materials can also be used.

KUKE has a dedicated team of pultrusion experts who can help guide manufacturers from product selection to process knowledge.

Contact Us

Telephone:

E-mail:

Address:

Room 821, Building 4, China Merchants Wanbo Mansion, Hanxi Avenue East, Nancun Town, Panyu District, Guangzhou City

©2024 Guangzhou KUKE Chemicals Co.,LTD. Business License

SEO Tags Power by:www.300.cn

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.