AIREX®R82

Product Details

DESCRIPTION

AIREX® R82 is a closed-cell, thermoplastic polymer foam that combines outstanding fire resistance with very low smoke and toxicity, along withexcellent dielectric properties.It has an outstanding strength to weight ratio, very low moistureabsorption, is thermoformable and ductile.

AIREX® R82 is an exceptional core material for use in structural lightweight applications that demand high fireresistance, radar transparency or operation in extremely hot or cold environments.

CHARACTERISTICS:

Fulfills most stringent fire requirements

Operating temperature from -194 °C to +160 °C (-317 °F to +320 °F)

Remains ductile at cryogenic temperatures

Excellent dielectric properties (radar outstanding transparency)

Very low moisture absorption

Good fatigue resistance

High impact resistance (non-brittle failure mode)

Thermoformable

Good sound and thermal insulation

APPLICATIONS:

|

|

|

|

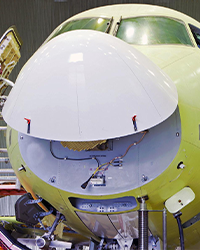

Aircraft and Aerospace: Interiors, cockpit doors, cryogenic tanks, insulating panels, radomes, helicopter

rotor blades, general aviation (fuselage and wing)

|

Road and Rail: Front-ends, side skirts, roof panels, interiors

|

Marine: Fast-ferries, fire resistant interiors, radomes

|

|

|

|

|

Defense: Naval superstructures, antennas, combat communication systems

|

Industrial: High temperature tooling, radomes, x-ray tables

|

PROCESSING:

Adhesive bonding

Thermoformable

Pre-preg processing (up to 180 °C, 355 °F)

Hot press molding

Thermoplastic processable

Automated tape laying (ATL/CTL)

AEROSPACE OUALIFICATIONS

|

Airbus: ABS 5609

|

Boeing: Multiple

|

Zodiac Aerospace: CDM 660

|

|

Bell Helicopter: BHS 299947304/ BPS

|

Northrup Grumman: Multiple

|

Diehl: DS-M0040

|

|

Liberty Aerospace: LMS 135A-925-001

|

|

Typical properties for AIREX® R82

|

Unit

(metric)

|

Value 1) |

R82.60

|

R82.80

|

R82.110

|

|

|

Density

|

ISO 845 | Kg/m3 |

Average

Typ. range

|

60 54-69 |

80 72-95 |

110 99-126 |

|

Compressive strength

perpendicular to the plane

|

ISO 844

ASTM C365

|

N/mm² |

Average Minimum |

0.70 0.60 |

1.1 0.9 |

1.6 1.3 |

|

Compressive modulus

perpendicular to the plane

|

DIN 53421 | N/mm² |

Average Minimum |

46 40 |

62 56 |

105

80

|

|

ASTM C365

|

Minimum

|

32 | 45 | 60 | ||

|

Tensile strength in the plane

|

ISO 527 1-2

|

N/mm² |

Average Minimum |

1.7 1.2 |

2.0 1.7 |

2.7

2.0

|

|

Tensile modulus in the plane

|

ISO 527 1-2

|

N/mm² |

Average

Minimum

|

45 35 |

54 50 |

80

60

|

| shear strength | ISO 1922 | N/mm² |

Average

Minimum

|

0.80 0.65 |

1.1 0.9 |

1.6

1.2

|

| shear modulus |

ASTM C393

|

N/mm² |

Average

Minimum

|

18 15 |

23 20 |

33

26

|

| ISO 1922 |

Average

Minimum

|

16

13

|

21

18

|

31

24

|

||

| Shear elongation at break | ISO 1922 | % |

Average

Minimum

|

25

15

|

23

13

|

17

9

|

| Impact strength | DIN53453 | KJ/m² | Average | 0.8 | 1.1 | 1.6 |

| Thermal conductivity at room temperature | ISO 8301 | W/m.K | Average | 0.036 | 0.037 | 0.040 |

| Foam slab | Width ²) | mm ±5 | 1350 | 1200 | 1000 | |

| Length ²) | mm ±5 | 2880 | 2700 | 2300 | ||

| Thickness | mm ±0.5 | 3 to 60 | 3 to 60 | 5 to 30 | ||

| Color |

off white

|

off white

|

off white

|

|||

Finishing Options, other dimensions and closer tolerances upon request

1) Statistical minimum values; test sample thickness 20 mm except tensile / impact properties (10 mm) and compressive modulus

(40 mm)

|

Fire performance

|

Standard

|

R82.60 | R82.80 | R82.110 |

| Aircraft | FAR 25.853/ABD0031 flammability FAR 25.853/ABD0031 Smoke Density ABD0031 toxicity FAR 25.853/ABD0031 Heat Release |

Passed Passed Passed Passed |

Passed Passed Passed Passed |

Passed Passed Passed Passed |

| Rail |

CEN TS 45545-2

|

HL32)

Final certification depending on sandwich

design

|

||

2) Indicative test; further details on request

The data provided gives approximate values for the nominal density and minimum values based on statistics.

The information contained herein is believed to be correct and to correspond to the latest state of scientific and technical knowledge.

However, no warranty is made, either expressed or implied, regarding its accuracy or the results to be obtained from the use of such information. No statement is intended or should be construed as a recommendation to infringe any existing patent.

|

Typical properties for AIREX® R82

|

Unit

(metric)

|

Value 1) |

R82.60

|

R82.80

|

R82.110

|

|

|

Density

|

ISO 845 |

lb/ft³

|

Average

Typ. range

|

3.75

3.4 - 4.3

|

5.0

4.5 - 5.9

|

6.85

6.2 - 7.9

|

|

Compressive strength

perpendicular to the plane

|

ISO 844

ASTM C365

|

psi

|

Average Minimum |

100

87

|

160

131

|

232

189

|

|

Compressive modulus

perpendicular to the plane

|

DIN 53421 |

psi

|

Average Minimum |

6’700

5’800

|

9’000

8’120

|

15’229

11’603

|

|

ASTM C365

|

Minimum

|

4‘640

|

6‘500

|

8‘702

|

||

|

Tensile strength in the plane

|

ISO 527 1-2

|

psi

|

Average Minimum |

250

174

|

290

247

|

392

290

|

|

Tensile modulus in the plane

|

ISO 527 1-2

|

psi

|

Average

Minimum

|

6’500

5’075

|

7’800

7’250

|

11’603

8’702

|

| shear strength | ISO 1922 |

psi

|

Average

Minimum

|

120

94.3

|

160

131

|

232

174

|

| shear modulus |

ASTM C393

|

psi

|

Average

Minimum

|

2’610

2’175

|

3’300

2’900

|

4’786

3’771

|

| ISO 1922 |

Average

Minimum

|

2’320

1885

|

3’045

2’610

|

4’496

3’480

|

||

| Shear elongation at break | ISO 1922 | % |

Average

Minimum

|

25

15

|

23

13

|

17

9

|

| Impact strength | DIN53453 |

Ft.lb/in²

|

Average |

0.38

|

0.52

|

0.76

|

| Thermal conductivity at room temperature | ISO 8301 |

BTU.in/ft2.hr.°F

|

Average |

0.25

|

0.26

|

0.28

|

| Foam slab | Width |

in ± 0.2

|

53.1

|

57.2

|

39.4

|

|

| Length |

in ± 0.2

|

110.2

|

106.3

|

90.6

|

||

| Thickness |

in ± 0.02

|

⅛ to 2.3

|

⅛ to 2.3

|

⅕ to 1.2

|

||

| Color |

off white

|

off white

|

off white

|

|||

Finishing Options, other dimensions and closer tolerances upon request

1) Statistical minimum values; test sample thickness 20 mm except tensile / impact properties (10 mm) and compressive modulus (40 mm)

|

Fire performance

|

Standard

|

R82.60 | R82.80 | R82.110 |

| Aircraft | FAR 25.853/ABD0031 flammability FAR 25.853/ABD0031 Smoke Density ABD0031 toxicity FAR 25.853/ABD0031 Heat Release |

Passed Passed Passed Passed |

Passed Passed Passed Passed |

Passed Passed Passed Passed |

|

Rail

|

CEN TS 45545-2

|

HL32)

Final certification depending on sandwich

design

|

||

2) Indicative test; further details on request

The data provided gives approximate values for the nominal density and minimum values based on statistics.

The information contained herein is believed to be correct and to correspond to the latest state of scientific and technical knowledge.

However, no warranty is made, either expressed or implied, regarding its accuracy or the results to be obtained from the use of such information. No statement is intended or should beconstrued as a recommendation to infringe any existing patent.

material for making fireproof

Classification:

Structural sandwich material 2

Key words:

Structural sandwich material 2

passed

average

minimum

Hotline:

Related Products

Leave Us A Message

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:13922295167